Specifying and Project Management of Automated Powder Coating Line

Client

Australia's Premier Lighting Manufacturer

Services provided

Background

Australia’s premier lighting manufacturer located in Melbourne engaged KAL Global to undertake the schematic design, project specification and procurement oversight of a turnkey semi-automatic powder coating line.

The Challenge

KAL Global’s customer was faced with a number of product quality and delivery issues relating to its subcontractors which were performing this critical powder coating process. This lack of control of this critical finishing process was thus causing customer issues and reputational damage to the company.

The Solution

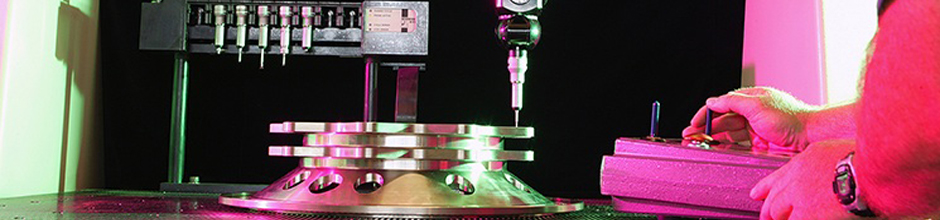

The solution for our firm’s lighting manufacturer was to install its own powder coating line. This project involved a pre-treatment tank line, drying oven, fully programmable overhead hoists, a manual powder booth and filtration system and powder curing oven. The pre-treatment line was a closed loop system utilising regenerative ion exchange resin columns with no waste water discharge.

Results

Initially KAL Global’s customer believed the new powder coating line would be used for urgent high specification work and that the bulk of the powder coating requirements would continue to be sub-contracted. The plant has proven otherwise as being easy to operate and producing a very consistent and quality product. Overall system performance has far exceeded KAL Global’s customer’s expectations.